INGLESE Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irur

FlareMaXGTG® – Gas To Gypsum

FlareMaXGTG® – Gas To Gypsum

FlareMaXGTG® – Gas To Gypsum

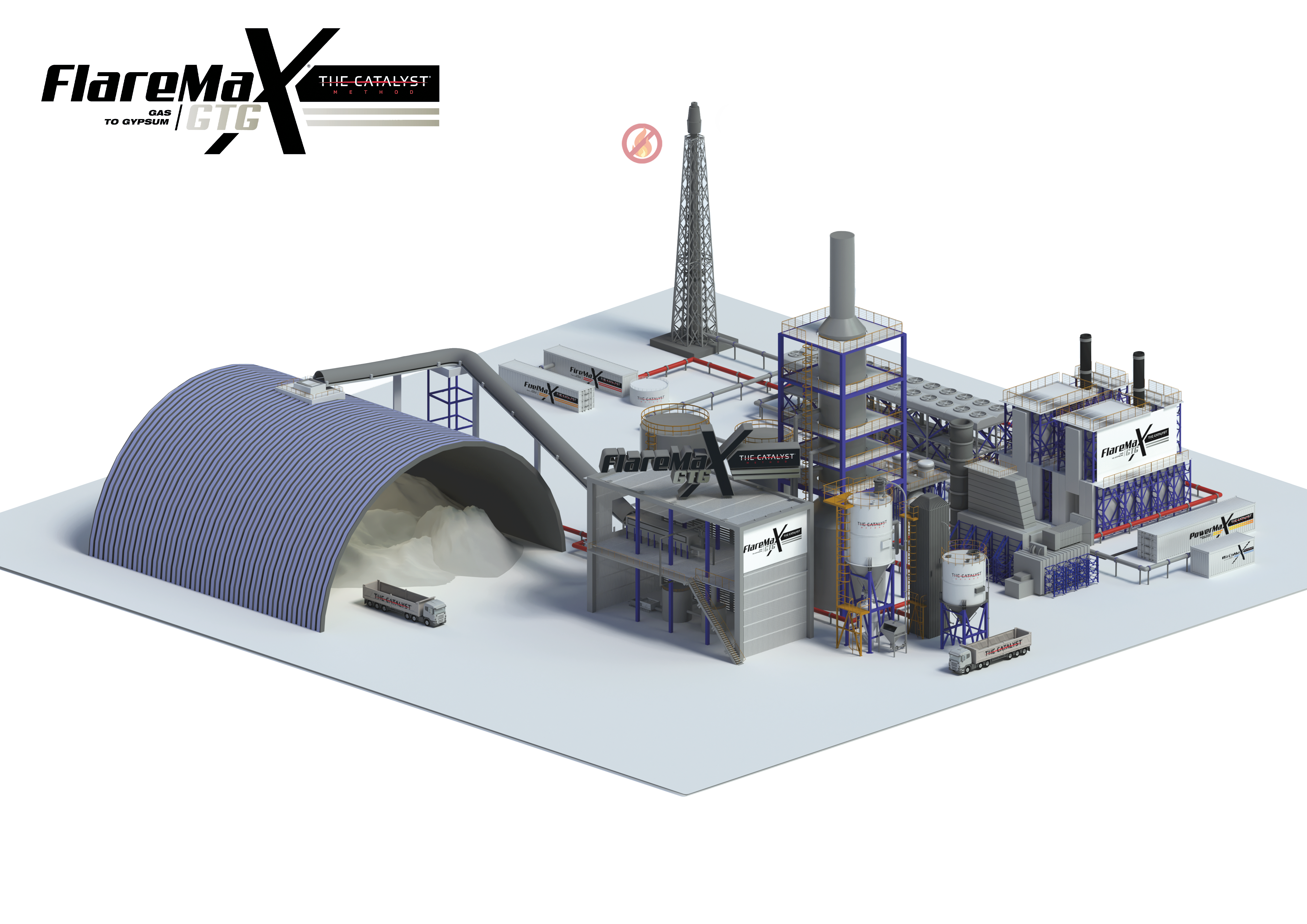

FlareMaXGTG® is modular Gas-To-Gypsum unit based on the direct conversion of Natural, Associated and Flare Gas into Gypsum, Electrical Power and Steam (Heating Media) through the Desulphurization (FPD) Technology. FlareMaXGTG® is a solution for the disposal of acid gas and the waste H2S product from the existing and future production facilities

Key Features & Benefits

FlareMaXGTG® is modular Gas-To-Gypsum unit based on the direct conversion of Natural, Associated and Flare Gas into Gypsum, Electrical Power and Steam (Heating Media) through the Desulphurization (FPD) Technology. FlareMaXGTG® is a solution for the disposal of acid gas and the waste H2S product from the existing and future production facilities

Key Features & Benefits

- Eliminates flaring in an economically feasible manner.

- 5.97 Ton of Gypsum is Produced per Ton of H2S in the inlet gas. No Sulphur is produced.

- 30% smaller foot-print than traditional unit.

- Modular, compact design.

- Lower CAPEX and OPEX than a traditional plant.

- No special storage requirements, i.e. gypsum can be stored safely on the ground in an open environment.

- No catalyst investment and replacement costs and typically 40 to 50 percent lower maintenance costs.

- No-grid electricity required.

- Excess and residual steam after power generation can be used for meeting plant heating requirements.