INGLESE Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irur

FlareMaXGTL® – Gas To Liquid Fuels

FlareMaXGTL® – Gas To Liquid Fuels

FlareMaXGTL® – Gas To Liquid Fuels

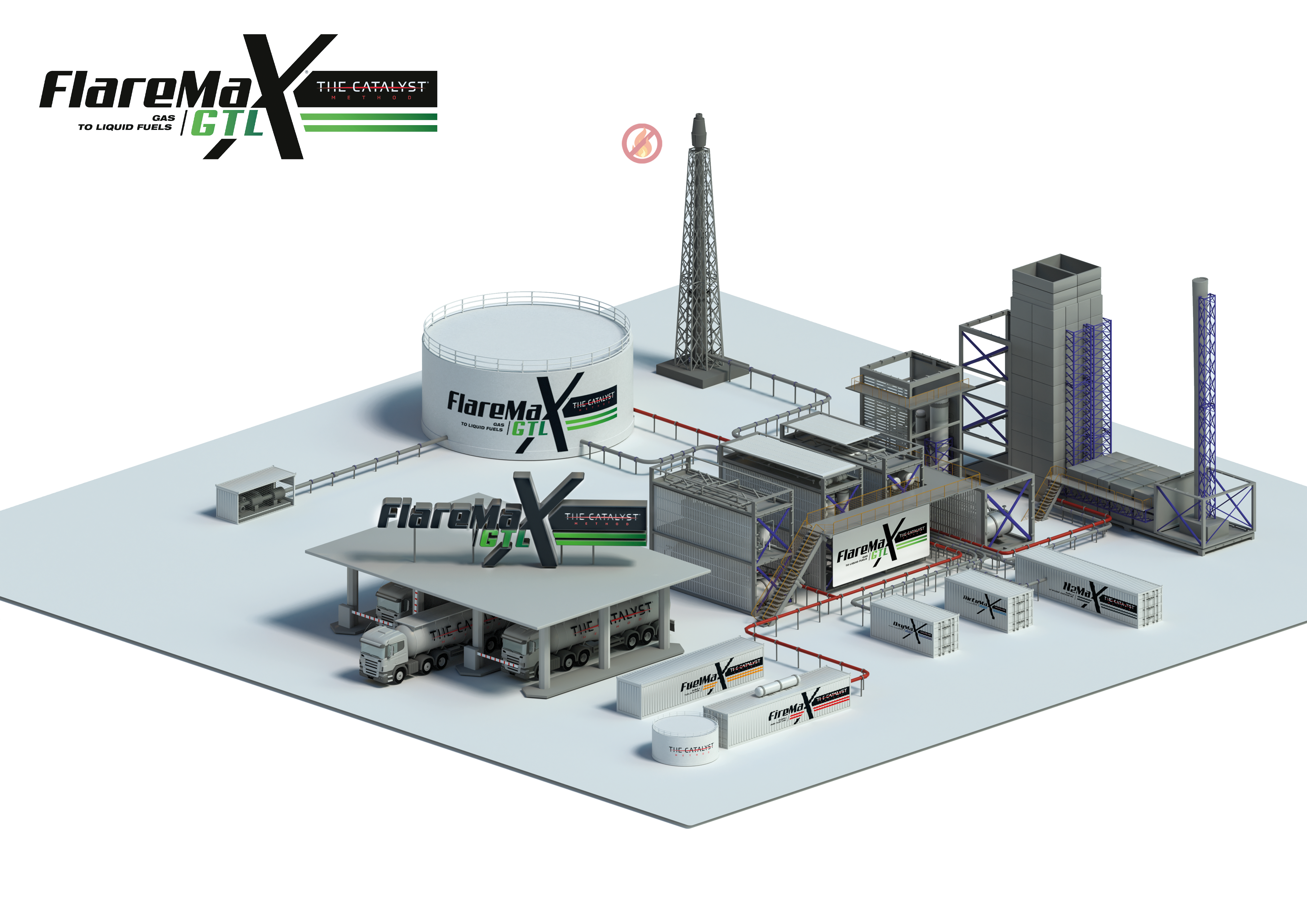

FlareMaXGTL® is modular Gas-To-Liquids unit based on the direct conversion of Natural, Associated and Flare Gas into synthetic liquid fuel. This liquid is produced directly from the reactor with no hydro-cracking required, and consists of a blend of diesel and gasoline fractions. A FlareMaXGTP® unit and water recovery block will be added as needed to the basic gas-to-liquid plant configuration to accomplish a self-sustaining plant without the need of an external source of electricity and water.

Key Features & Benefits

FlareMaXGTL® is modular Gas-To-Liquids unit based on the direct conversion of Natural, Associated and Flare Gas into synthetic liquid fuel. This liquid is produced directly from the reactor with no hydro-cracking required, and consists of a blend of diesel and gasoline fractions. A FlareMaXGTP® unit and water recovery block will be added as needed to the basic gas-to-liquid plant configuration to accomplish a self-sustaining plant without the need of an external source of electricity and water.

Key Features & Benefits

- Eliminates flaring in an economically feasible manner.

- Converts 1 million standard cubic feet of gas per day into 100 barrels of premium synthetic crude.

- High value.

- No by-products.

- Easily relocated. Modular, compact and movable containerized design.

- Low CAPEX and OPEX.

- Synthetic crude is fully compatible with the existing oil infrastructure and is easily upgradable to diesel.

- Processes feed gas with varying density.

- Handles CO2 rich gas (up to 25% in feed increases the productivity).

- Self-sustained process (no-grid electricity and no fresh water required).

- No requirement for continuous flaring.